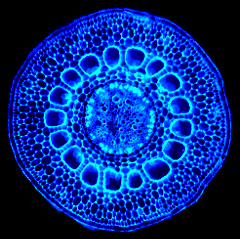

New look at old structure for future possibilities

Recent investigations have shown the incredible potential of an extremely common material, suggesting simple cellulose may have a strong future.

Recent investigations have shown the incredible potential of an extremely common material, suggesting simple cellulose may have a strong future.

It turns out the same tiny crystals that give trees and plants their high strength, light weight and resilience, have now been shown to have the stiffness of steel.

Researchers say organic cellulose might be used to create a new class of biomaterials with wide-ranging applications, such as strengthening construction materials and automotive components.

Calculations by engineering researchers at Purdue University in the US have shown the atomic structure of cellulose has a stiffness of 206 gigapascals, comparable to steel.

The discovery of its high strength has created quite a stir amongst the interested community.

“This is a material that is showing really amazing properties,” said Purdue University professor of civil engineering Pablo D. Zavattieri.

“It is abundant, renewable and produced as waste in the paper industry.”

“It is very difficult to measure the properties of these crystals experimentally because they are really tiny,” Zavattieri said.

“For the first time, we predicted their properties using quantum mechanics.”

The finding represents a milestone in understanding the fundamental mechanics of cellulose nanocrystals.

“It is also the first step towards a multi-scale modelling approach to understand and predict the behaviour of individual crystals, the interaction between them, and their interaction with other materials,” Zavattieri said.

“This is important for the design of novel cellulose-based materials as other research groups are considering them for a huge variety of applications, ranging from electronics and medical devices to structural components for the automotive, civil and aerospace industries.”

The cellulose nanocrystals represent an environmentally-friendly alternative to carbon nanotubes for reinforcing materials such as polymers and concrete.

Applications for biomaterials made from the cellulose nanocrystals might include biodegradable plastic bags, textiles and wound dressings; flexible batteries made from electrically conductive paper; new drug-delivery technologies; transparent flexible displays for electronic devices; special filters for water purification; new types of sensors; and computer memory.

The possibilities with cellulose are vast.

“Some of the byproducts of the paper industry now go to making biofuels, so we could just add another process to use the leftover cellulose to make a composite material,” said Robert Moon, a researcher from the U.S. Forest Service's Forest Products Laboratory.

“The cellulose crystals are more difficult to break down into sugars to make liquid fuel. So let's make a product out of it, building on the existing infrastructure of the pulp and paper industry.

“For example, you might want to modify the surface so that it binds strongly with a reinforcing polymer to make a new type of tough composite material, or you might want to change the chemical characteristics so that it behaves differently with its environment,” Moon said.

“Cellulose nanomaterials are inherently renewable, sustainable, biodegradable and carbon-neutral like the sources from which they were extracted... they have the potential to be processed at industrial-scale quantities and at low cost compared to other materials.”

More information is available in the full report, accessible here.

Print

Print