Ammonia advance reported

New techniques promise energy-friendly ammonia production for fertilisers and alternative fuel.

New techniques promise energy-friendly ammonia production for fertilisers and alternative fuel.

Researchers at the RIKEN Center for Sustainable Resource Science in Japan have made a significant breakthrough in ammonia production.

Led by Satoshi Kamiguchi, the research introduces a new catalyst that significantly reduces the energy and cost involved in synthesising ammonia by operating effectively at lower temperatures.

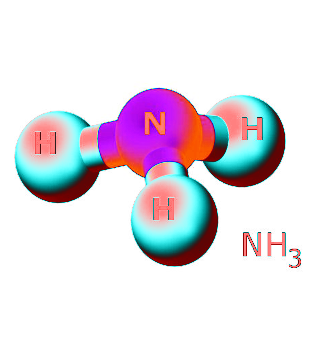

Ammonia plays a crucial role not only as a primary ingredient in fertilisers but also as a potential green alternative fuel.

Traditionally, its production through the Haber–Bosch process demands high temperatures and pressures, consuming substantial energy and consequently contributing to environmental concerns.

The new catalyst developed by Kamiguchi and his team involves ultrasmall molybdenum metal particles, activated with hydrogen gas, capable of efficiently breaking the robust nitrogen-nitrogen bonds at just 200°C.

This advancement allows continuous ammonia production over 500 hours, presenting a significant improvement over the conventional method.

This innovation holds promise beyond agriculture.

“Replacing the Haber-Bosch process with our new method should result in worldwide energy-saving,” Kamiguchi explains.

“If ammonia fuel and hydrogen fuel are used in much larger amounts, vastly reducing the energy needed to synthesise ammonia will lead to lower CO2 emissions and help prevent further global-warming.”

However, challenges remain, particularly in sourcing the hydrogen required for this process, which is predominantly derived from fossil fuels.

The next phase of research will focus on integrating this catalyst system with green hydrogen production to further reduce CO2 emissions, thereby contributing to a sustainable and eco-friendly energy landscape.

The full study is accessible here.

Print

Print