Add-on brings big leap in carbon scrubbing

The U.S. Department of Energy has funded a big breakthrough in the removal of carbon dioxide (CO2) from coal-fired power plants.

The U.S. Department of Energy has funded a big breakthrough in the removal of carbon dioxide (CO2) from coal-fired power plants.

Governments and energy companies around the world hope that the destructive influence of coal-fired power plants can be reduced by way of CO2 scrubbing – techniques that reduce the amount of harmful emissions that escape from the plants.

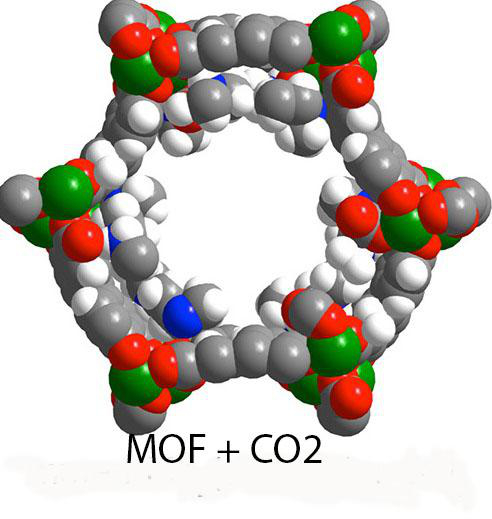

In a recent project in the US, Berkeley Lab researchers added a diamine molecule to the sponge-like solid scrubbing materials known as metal-organic-frameworks (MOFs).

The researchers were able to more than triple the CO2-scrubbing capacity of the MOFs, while significantly reducing parasitic energy.

About 13 billion tonnes of carbon dioxide are released into the atmosphere each year as a result of burning coal for the production of electricity.

These emissions are major contributors to global climate change and the acidification of our planet's oceans, but given that new coal finds are still happening, burning coal in power plants will continue to be a central source electricity for the foreseeable future.

Current carbon capture and storage technologies are typically based on aqueous amine scrubbers, but these come with a big energy cost.

So, MOFs have been proposed as a highly promising alternative to amine scrubbers.

Consisting of a metal centre surrounded by organic ‘linker’ molecules, MOFs form a highly porous three-dimensional crystal framework with an extraordinarily large internal surface area.

In fact, a MOF the size of a sugar cube if unfolded and flattened would blanket a football field.

In fact, a MOF the size of a sugar cube if unfolded and flattened would blanket a football field.

By altering their composition, MOFs can be tailored to serve as highly effective storage vessels for capturing and containing carbon dioxide.

In the latest effort, the addition of the diamine to the metal sites set off a chain reaction of events in which the carbon, metal and amines cooperatively reconfigured into the ammonium carbonates that enabled CO2 isotherm adsorption.

“With our technique, large CO2 separation capacities can be achieved with small temperature swings and regeneration energies that are appreciably lower than what can be achieved with state-of-the-art aqueous amine solutions,” says Jeffrey Long, a chemist with Berkeley Lab's Materials Sciences Division.

“We now understand how this CO2 cooperative process works and should be able to use the mechanism to design highly efficient adsorbents for removing CO2 from various gas mixtures.”

More details are available in the report titled “Cooperative insertion of CO2 in diamine-appended metal-organic frameworks.”

Print

Print